Ceramic Vortex Finder

Improve cyclone operations at high temperatures

Vortex finders (also known as center pipes, dip tubes, immersion tubes, and thimbles) in cyclones are essential as energy savers by optimizing particle separation and improving the thermal efficiency of the system.

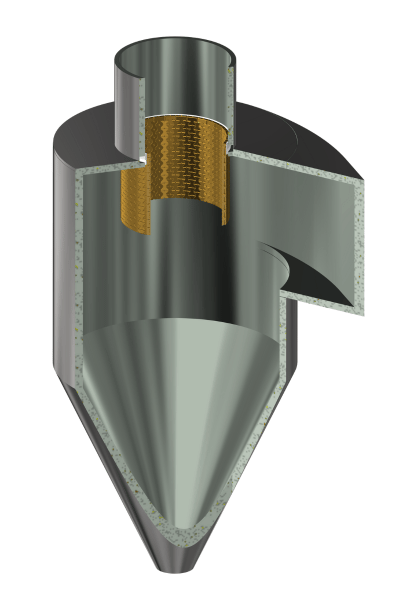

The HASLE Ceramic Vortex Finder (CVF) is designed to improve and sustain operations in industrial cyclones at elevated temperatures and provides an alternative to traditional steel dip tubes.

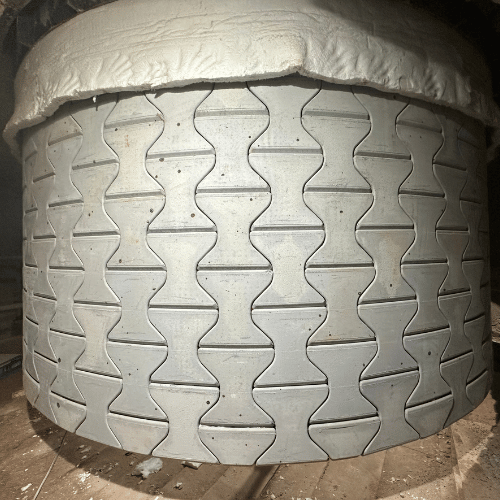

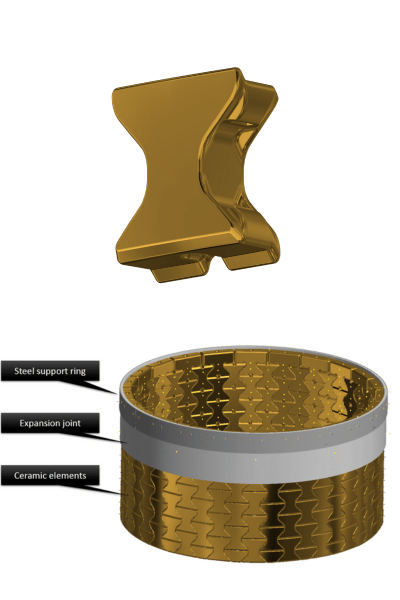

It is assembled on-site by individual ceramic elements, which interlock to form a stable tube hanging from a steel ring welded to the roof casing of the cyclone.

- Can withstand temperatures up to 1200 °C / 2200 °F

- No corrosion – excellent resistance to chemical attacks

- Does not buckle – high strength and dimensional stability

- Smooth surface – minimal build-up and coating

- The ceramic elements do not contains chromium, and is therefore safer and less complicated to maintain and service than its steel counterparts

- Easy and quick to install

Designed for longevity and to streamline your process

Minimizing the risk of blockage

The small-sized ceramic elements mean minimum risk of cyclone blockage if any of the elements fall down, as they can pass through the feed pipe and allow operations to continue.

Easy handling

Due to the low weight of 6-19 kg of the individual elements, no heavy lifting equipment is required for handling and it is possible to use the existing manholes for the installation.

Engineered to withstand the harsh conditions in cyclones

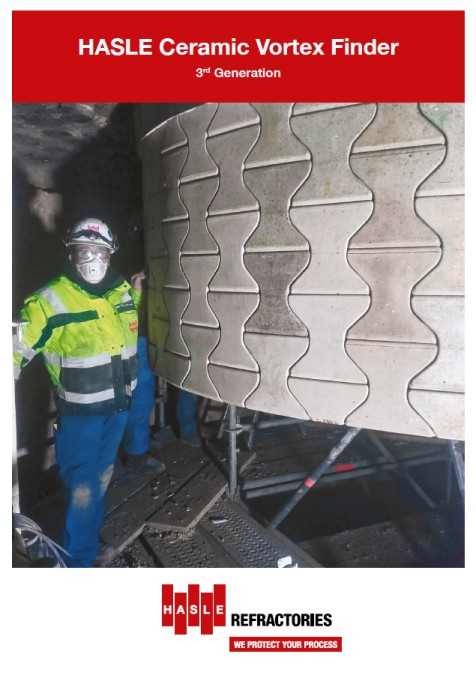

Originally developed in the 1980s, the latest generation 3 of the HASLE Ceramic Vortex Finder (CVF) is completely re-engineered specifically developed to cope with modern plant operations.

It is a general overhaul of the existing CVF product line boasting an optimized element design geometry and a new, unique high-performance refractory material, ensuring long life endurance between yearly campaigns.

Keep your process running with high efficiency!

The CVF is developed to withstand the aggressive production environments present in cyclones operating at high temperatures, including when firing alternative fuels.

As a result, the CVF is capable of withstanding temperatures up to 1200°C (2200°F) without deformation or creep, and exhibits high dimensional stability. In combination with high corrosion resistance, this ensures that the CVF does not buckle and maintains a high separation efficiency throughout its service life.

The smooth surface of the CVF elements minimizes build-up and coating, even in presence of agressive gasses.

Get aquainted with the HASLE Ceramic Vortex Finder

Modular system design for maximum flexibility

The HASLE Ceramic Vortex Finder (CVF) is based on a modular system of ceramic elements, which makes it possible to tailor the installation to individual operating conditions and cyclone dimensions.

The CVF system consists of standardized shapes in different angles which interlock via advanced tongue-and-groove joints, allowing:

- Variable diameter options: 1,5m – 7,5m

- Lengths up to 5 m

Meticulous manufacturing

High-performance materials

The ceramic elements are manufactured from a high-grade castable with pure synthetic and high-performance raw materials to ensure no impurities. Nanoparticles are included for high fracture toughness and optimal strength – even at elevated temperatures. In addition, the materials used are providing high resistance to chemical attacks, making the CVF suitable for plants burning alternative fuels.

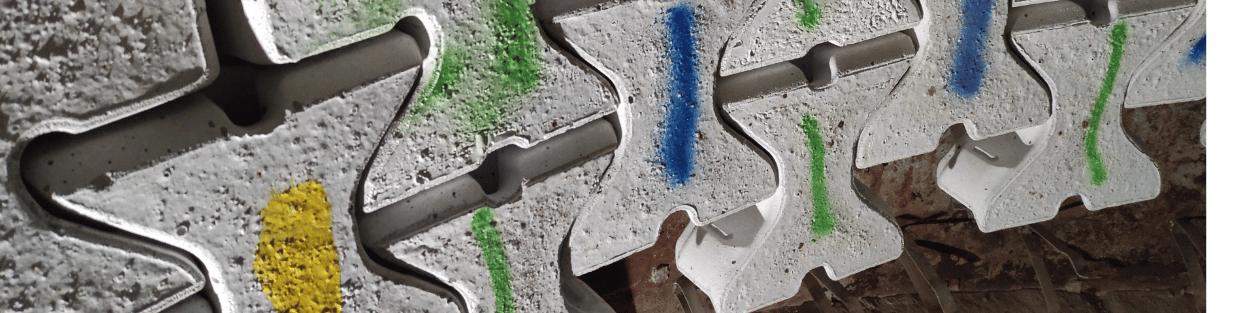

Carefully manufactured for maximum strength

To achieve maximum strength, the ceramic elements are manufactured under strictly controlled conditions at our factory in Denmark; first, the shapes are carefully cast and cured in specialized molds to obtain a smooth surface and sustain their unique profile. Subsequently, they are pre-fired to elevated temperatures.

Selected references

Since the introduction in the 1980s, several hundres of the HASLE Ceramic Vortex Finder have been installed globally. Especially in the lower-stage cyclones of the prehating process in cement plants. But also in for instance paper mills, wood processing plants, aluminum smelters and in boiler applications for power generation.

Latest, the generation 3 of the CVF has been introduced to the market, and below you can read the most recent installation cases

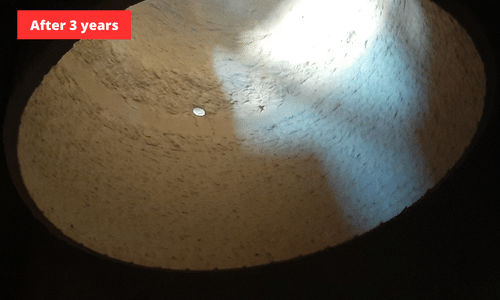

Cement plant in Germany – 2nd lowest stage cyclone

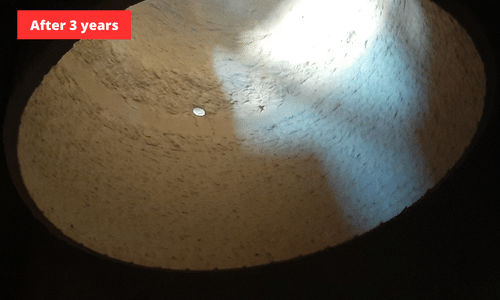

A 5.000 tpd cement plant in Germany operating on 82-95% RDF has installed a HASLE Ceramic Vortex Finder (generation 3) in the 2nd lowest stage cyclone in the preheating process, replacing a steel dip tube, which had a 3 year lifespan. Operating at temperatures around 850 °C, the CVF has now been in operation for more than 3 years and is still running.

Cement plant in Germany reach 1 year lifetime in lowest-stage cyclone

In the lowest-stage cyclone at a 5.000 tpd cement plant in Germany, a HASLE Ceramic Vortex Finder has acheived 1 year lifetime. The cement plant is running on 82-95% RDF and the operating temperature in the cyclone 950°C. The steel dip tube previously used had a 2-3 months lifespan.

Cement plant in Spain – middle-stage cyclone

Installed in January 2020, a Ceramic Vortex Finder is running on its 5th year at a Spanish cement plant. It is installed in the middle stage cyclone, which operates at ca. 700 °C. The plant is utilizing 60% alternative fuels.

Cement plant in Spain – middle-stage cyclone

Installed in January 2020, a Ceramic Vortex Finder is running on its 5th year at a Spanish cement plant. It is installed in the middle stage cyclone, which operates at ca. 700 °C. The plant is utilizing 60% alternative fuels.

Cement plant in Oceania – Lowest-stage Cyclone

At a 4000 tpd cement plant in Oceania, operating on natural gas and 40% RDF, there was no dip tube installed in the lowest stage cyclone, which operates at approximately 850-900°C. In January 2023, the plant installed a Gen3-CVF, which has now achieved a one-year lifetime and is still in operation.