Cement

We protect your process

HASLE Refractories A/S has been manufacturing refractory products for more than 100 years, and over the years obtained a vast experience about the challenges to be met in today’s highly efficient cement industry.

In close cooperation with our customers, we analyze problems in the most critical areas in order to identify the solutions which will secure our customers’ kiln a higher run factor at a lower total cost.

HASLE Low Cement Castables (LCC’s) are characterized by having a very dense and strong matrix developed to withstand the challenges of modern cement production, where alternative fuels are customary. Alkali-resistant castables with low, open porosity and high strength based on best quality refractory raw make up the backbone of our product range.

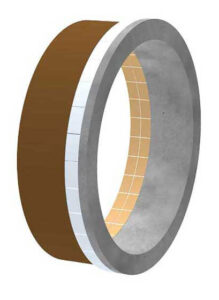

Depending on the conditions in the critical area, we offer a wide range of solutions. From the fast gunning repair with very low rebound (less than 10%) to the traditional in-situ casting or the maximum lifetime solution; the well-known precast Modular Lining.

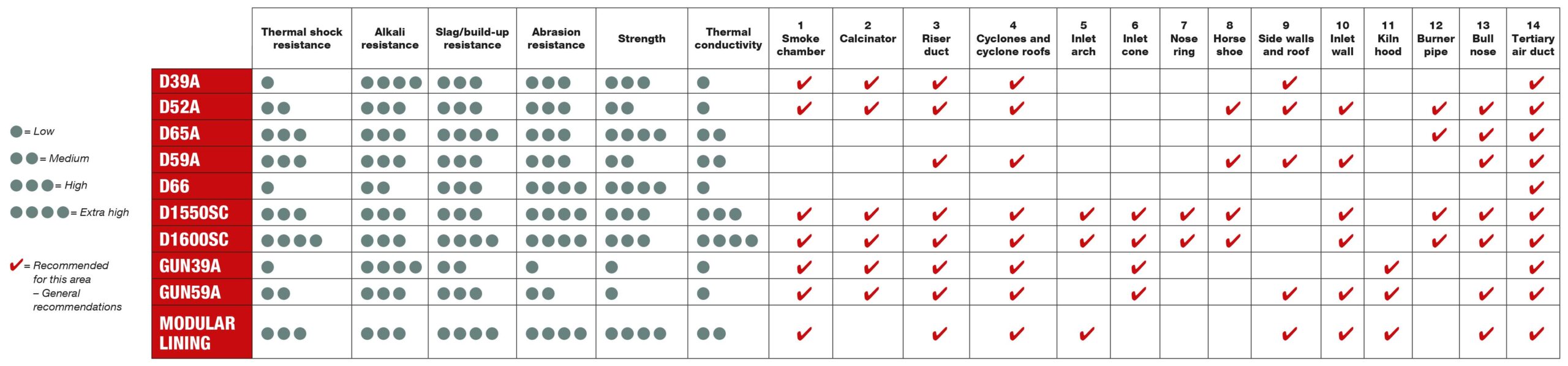

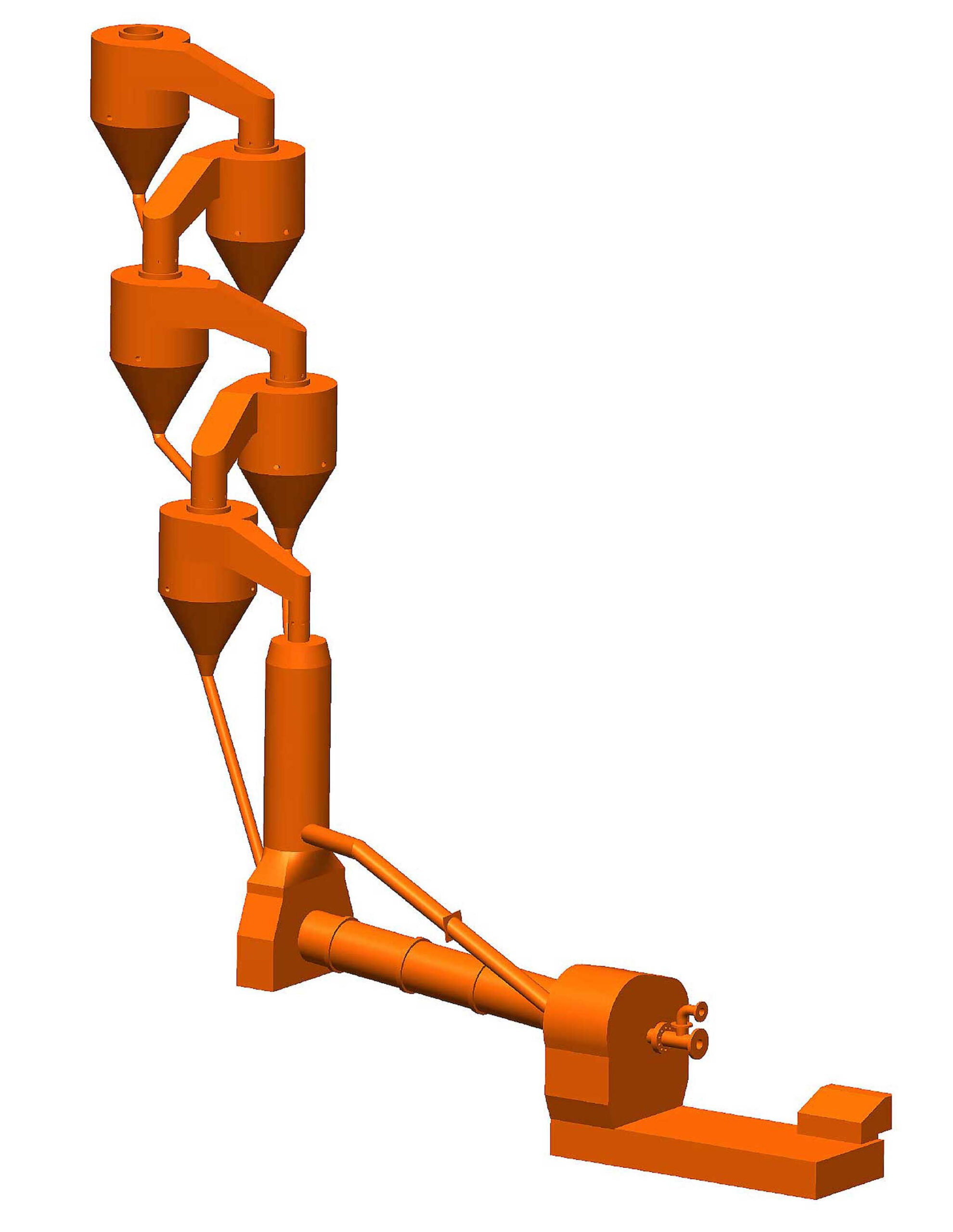

Find the right solution for your process

Click on the number by the various areas to see what problems typically occur. Find the number in the table below to see our recommended solution.

Smoke Chamber: Coating problems due to using a high percentage of alternative fuels. (Increased S, Cl, Alkalies). Partial repair is required in each campaign for LCC lining.

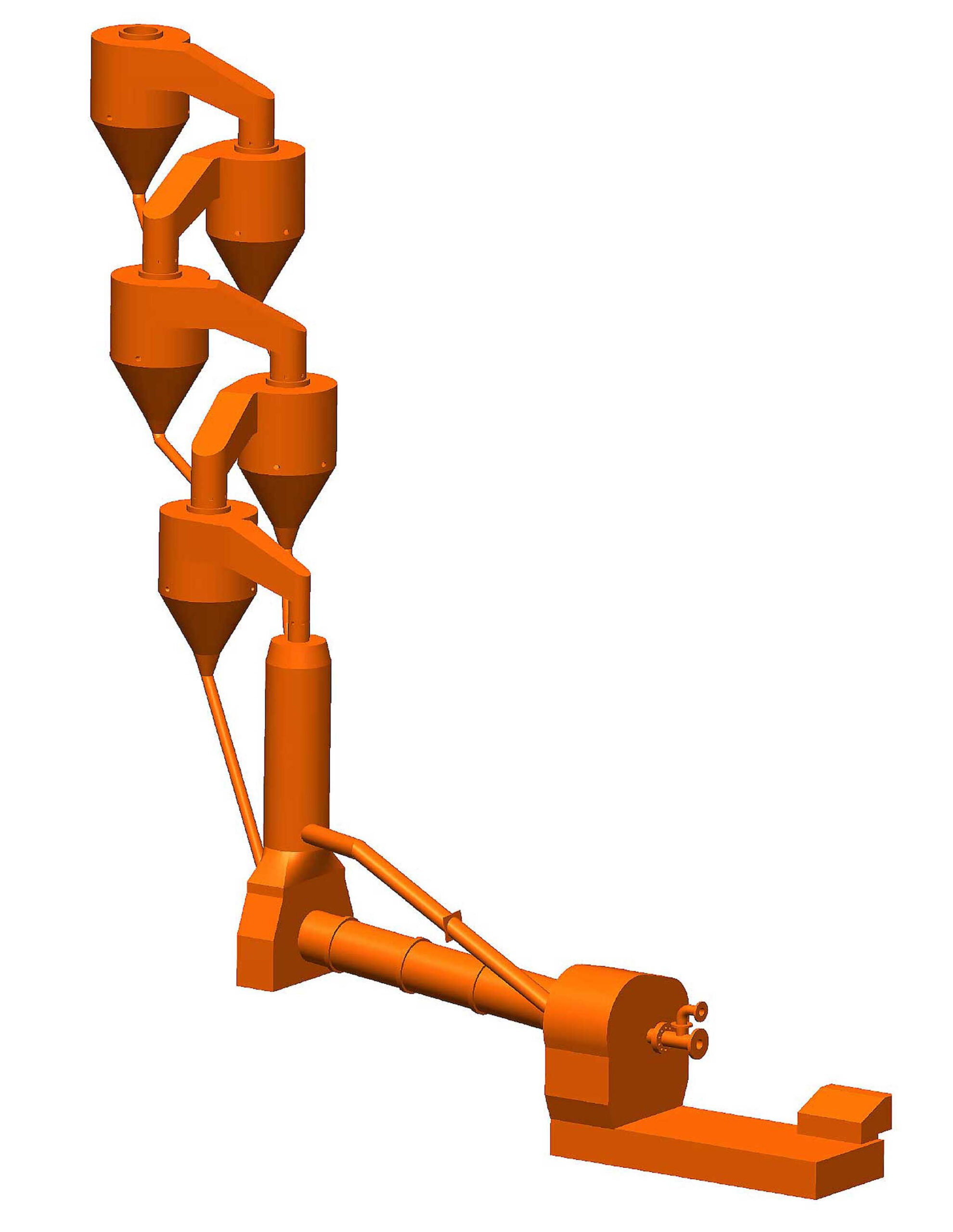

Calcinator: Prone to attack of alkalis and other chemicals from AFR and also heat from secondary burners used inside the calciner. Partial repair required every year.

Riser Duct: Coating may restrict flow of material. Most chemical vapours deposit in this area as temperature is relatively low. Very much prone to chemical attack, requiring replacement of LCC every year.

Cyclones and Cyclone Roof: Chemical attack, coating and high abrasion in conical portions. Life of dip tubes inside cyclones is an issue if we focus on thermal efficiency.

Inlet Arch: Heavy erosion due to which replacement is required every year or every other year.

Inlet Cone: Prone to high abrasion and chemical attack. LCC needs to be replaced every year.

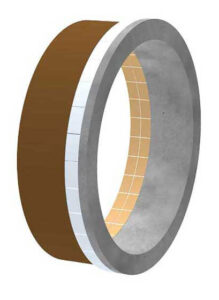

Nose Ring: Prone to severe abrasion, severe chemical attack, highest temperature and thermal shock. Needs to be replaced after every campaign.

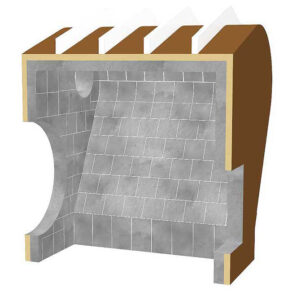

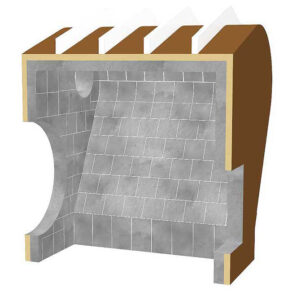

Horse Shoe: Severe abrasion caused by very hot clinker movement. Partial repair required after every campaign.

Side Walls and Roof (Cooler): Abrasion due to clinker dust impact and high temperature gases in primary grate cooler. Needs partial repair every year.

Inlet Wall (Front Wall): High abrasion due to falling clinkers. Also, coating leads to pile-up of clinker in this area. Major repair needed during every annual shutdown.

Kiln Hood: High abrasion from high speed hot clinkers and chemical attack from gases from burning of fuel.

Burner Pipe: Severe abrasion (from hot and high-speed clinker dust) and chemical attack. Prone to extreme thermal shock and highest temperature in the zone.

Bull Nose: Severe abrasion from very hot clinker dust. Also prone to thermal shock as area is located near kiln main door.

Tertiary Air Duct: Prone to severe abrasion from high-speed clinker dust from cooler to pre-heater.

Smoke Chamber: Coating problems due to using a high percentage of alternative fuels. (Increased S, Cl, Alkalies). Partial repair is required in each campaign for LCC lining.

Calcinator: Prone to attack of alkalis and other chemicals from AFR and also heat from secondary burners used inside the calciner. Partial repair required every year.

Riser Duct: Coating may restrict flow of material. Most chemical vapours deposit in this area as temperature is relatively low. Very much prone to chemical attack, requiring replacement of LCC every year.

Cyclones and Cyclone Roof: Chemical attack, coating and high abrasion in conical portions. Life of dip tubes inside cyclones is an issue if we focus on thermal efficiency.

Inlet Arch: Heavy erosion due to which replacement is required every year or every other year.

Inlet Cone: Prone to high abrasion and chemical attack. LCC needs to be replaced every year.

Nose Ring: Prone to severe abrasion, severe chemical attack, highest temperature and thermal shock. Needs to be replaced after every campaign.

Horse Shoe: Severe abrasion caused by very hot clinker movement. Partial repair required after every campaign.

Side Walls and Roof (Cooler): Abrasion due to clinker dust impact and high temperature gases in primary grate cooler. Needs partial repair every year.

Inlet Wall (Front Wall): High abrasion due to falling clinkers. Also, coating leads to pile-up of clinker in this area. Major repair needed during every annual shutdown.

Kiln Hood: High abrasion from high speed hot clinkers and chemical attack from gases from burning of fuel.

Burner Pipe: Severe abrasion (from hot and high-speed clinker dust) and chemical attack. Prone to extreme thermal shock and highest temperature in the zone.

Bull Nose: Severe abrasion from very hot clinker dust. Also prone to thermal shock as area is located near kiln main door.

Tertiary Air Duct: Prone to severe abrasion from high-speed clinker dust from cooler to pre-heater.

Download the chart to see the details of our recommended solutions for the individual areas of a cement plant.

“A wonderful achievement and it’s still in good shape. HASLE D59A is a miraculous castable!”

– Hassen Gharsalli

Process, performances and environment Manager, LafargeHolcim