we protect your process

We have several hundred references using either our Low Cement Castables, precast linings and our unique HASLE Ceramic Vortex Finder in boilers.

HASLE supplies material/pre-cast elements to amongst others: Foster Wheeler, Metso Power and Ahlstom.The size of the boilers we have lined ranges from only a few MW units to units of several hundred MW taking up to more than 1,000 tonnes of high quality refractory materials.

HASLE ISOMEMBRANE is a technology invented by HASLE to seal boiler leakages. It is applied on boiler penthouse area, the nose arch, the expansion joints or the bottom ash hoppers. For more information please contact our head office.

products

Castables

Raw materials with excellent chemical resistance

HASLE castables are manufactured on the basis of our own unique recipes.

Even though our recipes are considered being among the best in the world, we continuously invest in R&D and plant equipment and we have excellent references.

Why you should chose HASLE Castables:

› Premium Quality raw materials – proven recipes. In dept Quality Assurance based on ISO 9001:2015

› Flexible Production Plant located in Denmark – provides fast responsetime on orders of all sizes

› Gunning castables with very low rebound – reduces waste in the installation process

› Insulating castables completes your HASLE Refractory solutions.

Our castables:

Traditional, Low-cement, Gunning, Insulating and Mortars are manufactured in our highly automated plant and internal procedures ensure that we deliver a consistent, high quality. A detailed quality system secures that all castables leaving our factory comply with our high requirements on particle-size distribution, castability and physical properties.

In order to make the best quality of materials, we source only the very best raw materials – no recycled materials and no prefabs from other suppliers. At HASLE we are sourcing our raw materials from suppliers in 14 different countries all over the world. We are in no way depending on using local or domestic raw materials. We are free to choose the very best raw materials, and we do so.

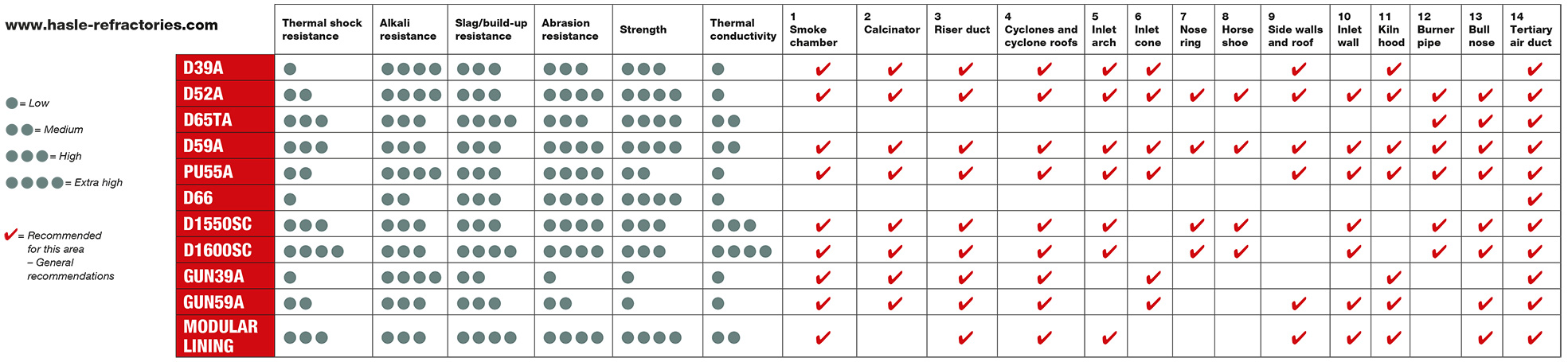

HASLE datasheet overview

Precast elements

HASLE manufactures precast modular elements developed by our own technicians in our plant in Denmark.

We offer to design and manufacture customer-specific elements in close collaboration with the customer and based on requirements like ease of assembly, durability and thermal conduction. Case stories for Precast Elements.

Why you should chose HASLE Precast Elements:

› Custom made solutions designed by HASLE with use of premium HASLE Castables

› Flexible Production Plant located in Denmark – provides fast responsetime on orders of all sizes

› Controlled production with a 100 % QC ensures very durable, precise and uniform elements

› Most effecient solution. Easy-to-install avoids the drying-out problems

There are many advantages of choosing a lining made of precast modular elements.

The combination of a high-quality low-cement castable with a controlled manufacturing ensures a very durable, precise and uniform element – which can be manufactured in all sorts of shapes.

HASLE can pre-fire elements in the range from 500°C to 1350°C depending on the application. Firing to 1350°C is a speciality of HASLE and it secures elements with outstanding characteristics.

Refractory solutions made of precast elements are easy to install, and the user avoids the drying-out problems that can be experienced by using castables. The process can be restarted very quickly without a risk of explosion due to vapours emitted by castables.

Ceramic Vortex Finder

Handling harsh operating conditionsact cyclones

The HASLE Ceramic Vortex Finder is manufactured in our own factory, and assembled from individual precast refractory elements which fit together to form a stable cylinder hanging from brackets in the cyclone roof.

Why HASLE CVF is a better alternative:

› Does not bucle or corrode

› No chronium Issues as it is Ceramic

› Reduces build-up (Build-up sticks less easily to the CVF)

› Quick and easy to install (6 – 16 hours)

› Fallen pieces rarely block the cyclone

The HASLE Ceramic Vortex finder (CVF) was first installed in cement kiln cyclones in the late 1980´s. Since that early start the development has continued and lifetimes have improved. During that time the steadily increased use of alternative fuels has caused more and more aggressive conditions in preheater cyclones.

In these environments the steel-alloy tubes are suffering more due to corrosion or buckling. The lifetimes have become shorter and fallen steel-alloy pieces can easily block the cyclone and/or damage the kiln or cooler or crusher. Where this is the case, the HASLE CVF is the correct alternative.

Guarantee

Each HASLE Ceramic Vortex Finder is supplied with a product guarantee, based on the operation conditions of your kiln. Please ask us for an unconditional offer and the related product guarantee.

Maintenance

The lifetime of the HASLE Ceramic Vortex Finder can be extended with regular inspections and necessary repairs. Depending on the working conditions an inspection should take place every 8 to 12 months.

The length of the HASLE Ceramic Vortex Finder can easily be adjusted during a kiln stop to suit changes in the process conditions.

Modular lining

Easy to install and Ready-To-Go Precast

The HASLE Modular Lining is factory made flexible precast refractory lining system for walls, roofs and curves. Element size designed for easy handling and installation. Insulation can be configured according to customer demands and wishes. Highly resistant to alkali attack and build up. Eliminates need for special dry-out arrangements and allows for faster restart of production.

The HASLE Modular is a layered construction consisting of a precast hotface element, a layer of castable/insulating castable, and in some cases a layer of calcium silicate insulation.

Benefits

Establishing a precast modular lining system in HASLE alkali resistant LCC castables offers the following benefits:

› reduces/eliminates coating problems (build-up)

› reduces maintenance

› improves insulation

› increases cross-sectional area of riser duct/feed pipe (with thinner lining)

› reduces installation time

In principle, the construction is the same for flat, conical, cylindrical and roof elements.The simple design of HASLE modular lining ensures easy and fast installation. The man-hours required for a typical lining vary between 5-10 mhs/m² or 10-20 mhs/ton. These rates depend on the condition of the actual area to be lined i.e. number of air blasters, inspection holes, manholes etc.

Technical design service

As experts in design, use of ceramic materials and manufacturing of precast elements, we are happy to help you design your precast elements.

Specially designed precast elements are used where high temperatures, alkali attacks, abrasion and/or thermal shock creates a challenging environment.

Partnering with HASLE already in the design phase enables you to tap into our vast experience in advanced technical design, use of ceramic materials and manufacturing of precast elements.

We can help ensure that your precast elements are made to meet your requirements and guide you in the most efficient way of production. We work with you from initial design to shipping of your precast elements.

We begin by establishing a common understanding of the requirements for your precast elements. Your technicians will meet our technicians and discuss the details of the application, conditions, dimensions, and any specific requirements which must be met.

Subsequently, HASLE provides a design suggestion and presents you with a draft, including a sketch and a commercial quotation.

If needed, HASLE is also able to provide 3D printed prototypes.

When an agreement on the design is reached, HASLE will complete the drawings and start preparing moulds for casting. Naturally, we make a test casting and ensure that all measurements are correct, and that all surfaces are up to the agreed QA standards. When approved, production begins.

Call us today for a discussion of your precast element design needs at +45 5695 1800

Refractory commodities

To supplement our own manufactured products, HASLE offers a wide range of ceramic fibres, insulating bricks and fireplace bricks.

Ceramic fibres

Ceramic fibre products are used wherever high insulatingcapacity is required. If mechanical wear is not present, ceramic fibres can be used as the only refractory material which is in contact with the process.

HASLE sells only synthetic bio-soluble fibres. The fibre is water soluble and therefore less harmful to human health than traditional ceramic fibres.

Insulating bricks

Insulating bricks are distinguished from other bricks by their high porosity and, thus, lower compressive strength. The advantage of insulating bricks is that they can be used for both primary lining and insulationbacking. They have good insulating capacity, good thermal resistance and provide a lightweight refractory structure.

Fireplace bricks

Used for building wood-burning stoves, small stoves and ceilings, etc. The bricks are made of chamotte and fire clay.

Isomembrane

HASLE ISOMEMBRANE is a technology invented by HASLE to seal boiler leakages. It is applied on boiler penthouse area, the nose arch, the expansion joints or the bottom ash hoppers.